With the continuous development of the transportation industry, port transportation has occupied an important position in the transportation industry due to its economic efficiency, large transport volume, and high cost performance.

At present, ports generally configure shiploaders with different production efficiencies according to the size of the ship. During the loading process, due to the different operating conditions of the telescopic chute mechanism, the safety protection device cannot provide comprehensive protection, leading to many different types of safety accidents.

Types of Telescopic Chutes

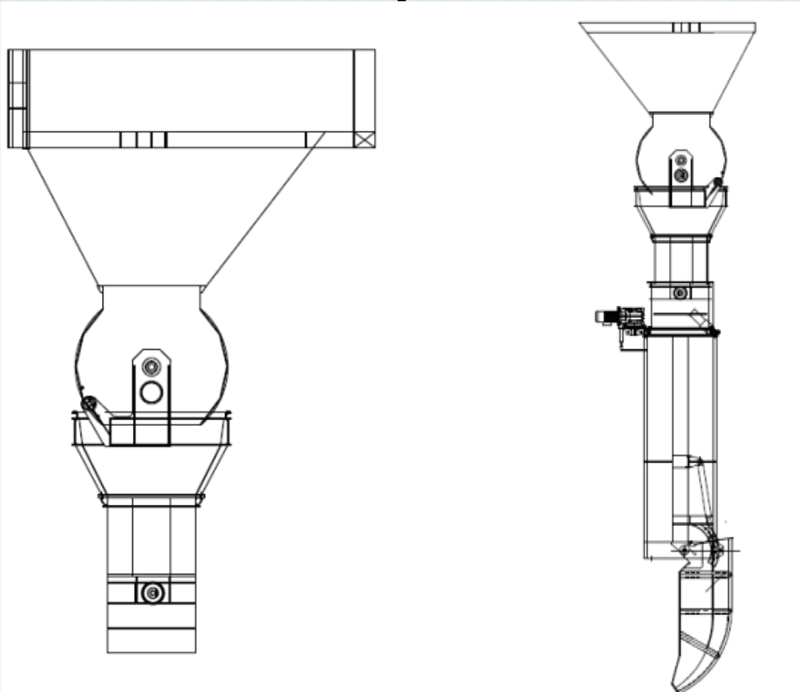

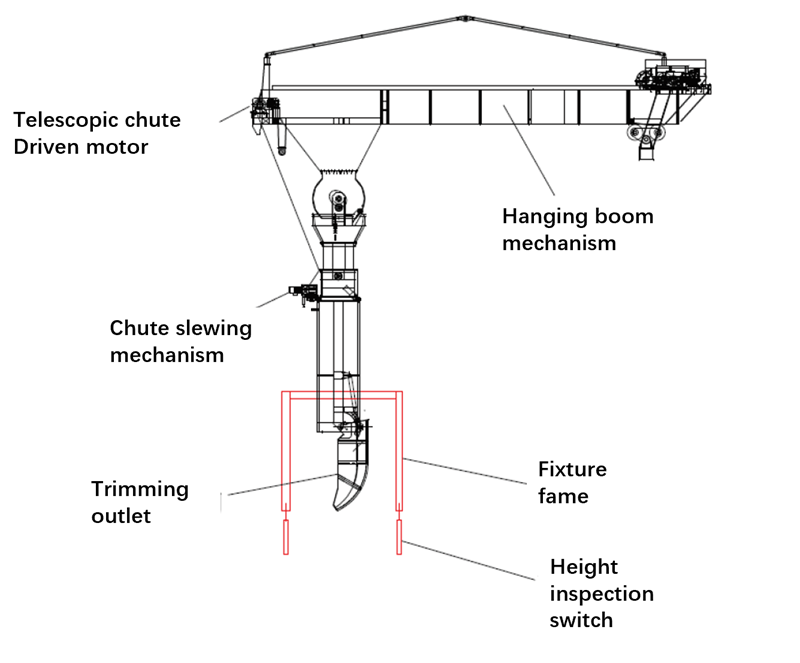

According to the size of the ship type and the depth of draft, shiploader telescopic chute mechanisms can be divided into two types: straight telescopic chutes and telescopic chutes with throwing scoops. The straight telescopic chute type is composed of a single or multiple circular cylinders, and the lifting or lowering of the chute is accomplished by a drive mechanism installed at the front end of the cantilever, as shown in Figure 1. When loading ships with deep drafts, large sizes, and complex shapes, a chute with a scoop is required because a straight telescopic chute cannot load the edge areas of the ship’s hold, as shown in the figure.

Safety Performance Analysis of Shiploader Telescopic Chute

With the expansion and extension of port loading operations, more and more domestic ports are equipped with shiploaders of different production efficiencies. Through analysis and summarization of the actual operating conditions of these ports, the following safety hazards of shiploaders have been identified:

(1) During loading operations, the telescopic chute is basically inside the ship’s hold. Due to the large amount of dust in the hold and insufficient visibility, the operator cannot clearly see the working condition of the telescopic chute during operation. At this time, there is a risk that the telescopic chute and the scoop will be buried by the material.

(2) During the process of changing compartments, the operator and on-site command personnel may not be able to observe the distance between the telescopic chute and the material bucket and the ship’s hull due to the angle of the boom and the telescopic chute. During the movement of the shiploader or the rotation of the boom, the telescopic chute and the material bucket may collide with the ship’s hull, causing a safety accident.

(3) When the telescopic chute is telescoping, rotating, or tilting forward or backward inside the ship’s hold, it is difficult for the operator to see whether the cable is tangled or squeezed against the steel structure, which can easily cause the cable to be pulled apart.

(4) When the shiploader is in standby mode, the cantilever is raised 25° upward, at which point the telescopic chute is at its highest point, and the operator cannot visually inspect the telescopic chute.

(5) Since material easily accumulates on the guide rails between each section of the telescopic chute, the guide rails are prone to jamming during the telescopic movement of the chute, which can cause unpredictable lifting resistance. When the chute is lifted, the uneven force on both ends can easily cause deformation of the chute, as well as breakage of the steel wire rope, resulting in the lower chute becoming detached and falling.

(6) Most shiploader telescopic chute mechanisms and material throwing bucket devices use hydraulic systems to control their front-to-back swing function. Due to the complexity of the telescopic chute mechanism, it is easy to cause malfunctions when performing various operations, and it is difficult to find the cause of the malfunction during maintenance. Even if the cause of the malfunction is found, the hydraulic station is located in the middle of the telescopic chute mechanism, making maintenance and inspection extremely difficult and posing a great danger to maintenance personnel. In recent years, the number of accidents occurring during the maintenance of shiploader telescopic chute mechanisms has continued to increase year by year.

Measures to Improve Safety Performance of Telescopic Chute

In order to address the above safety hazards, we can improve the safety of shiploader telescopic chute mechanisms by improving and optimizing the equipment. The main methods are as follows:

Anti-bottom contact device

The anti-bottom contact device is divided into two parts: collision detection and control. Two sets of tilt switches are installed on the side of the material throwing mechanism at the bottom of the telescopic chute. The height of the tilt switches is lower than that of the telescopic chute. When the bottom of the telescopic chute is about to be buried by materials or collide with the ship’s hold, the tilt switches will activate first. The signal is transmitted via shielded cables to the PLC module, displayed as a fault signal on the CMS interface, and simultaneously triggers the driver’s cabin fault buzzer alarm, ensuring the safety of personnel and equipment.

Inclination switch

A set of inclination switches is installed at the front and rear swing points of the telescopic chute, and a manual/automatic knob is set on the driver’s cab control panel. When the knob is set to automatic, the AB1756 PLC automatically calculates the vertical angle of the telescopic chute and, based on logical operations, automatically controls the front or rear swing of the telescopic chute so that it is always perpendicular to the ground, facilitating intuitive inspection by the operator.

Improved wire rope connection method

Referring to the connection method of the wire rope of the ship unloader’s pitching mechanism, a balance locking device is added to the middle of the telescopic chute drive wire rope. The balance locking device is used to fix the wire rope in the middle to improve the safety of the wire rope. When one end of the steel wire rope breaks, the other end of the steel wire rope fixed to the balancing locking device and the reel has sufficient tensile force to bear the weight of the lower telescopic chute, preventing the lower telescopic chute from disengaging and falling, and ensuring the safety of the telescopic chute.

Telescopic chute anchoring

When the shiploader is on standby (not in operation), strong winds or other reasons may cause the telescopic chute to swing back and forth, and frequent swinging of the telescopic chute mechanism can easily cause wear and breakage of the steel wire rope. In order to prevent such accidents, anchoring devices can be installed at the front and rear ends of the telescopic chute mechanism to prevent the telescopic chute mechanism from swinging.

Lifting restrictions

During the telescopic movement of the chute, it must be ensured that the steel wire rope is within the allowable tensile force and the motor is within the rated torque range to avoid deformation of the chute mechanism or breakage of the steel wire rope due to local resistance during the lifting process. The lifting limiter and motor torque protection can detect the stress on the steel wire rope under various working conditions and protect the safety of the chute mechanism by limiting the stress on the steel wire rope.

Blockage protection device

A set of blockage switches is installed on the side of the hopper near the bottom of the shiploader’s cantilever head. When the telescopic chute is blocked, the blockage switch emits an alarm signal and stops the loading operation through an electrical interlock.

Other aspects

Observation holes are set at the top of the telescopic chute and the bottom of the outer chute. When the telescopic chute is blocked, the cargo can be discharged in a timely manner through the observation hole. In some ports with colder weather, a heater is installed at the funnel above the telescopic chute to prevent material from freezing and causing blockages due to low temperatures.

Current Telescopic Chute Collision Prevention Technology

There are three types of telescopic chute collision prevention technology control methods: manual, semi-automatic, and fully automatic. In manual control mode, the operator stops the shiploader based on the feedback signals from the protective switches of the telescopic chute mechanism. In semi-automatic or fully automatic control mode, the telescopic chute protection device only participates in the program logic control of the telescopic chute mechanism after it has been activated.

When the shiploader is set to semi-automatic operation, the driver can set the initial position of each mechanism of the shiploader based on the actual conditions such as the ship type and draft. For example

In fully automatic operation, the shiploader’s fully automatic control can actively scan the pile shape inside the ship’s hold using a 3D laser scanner. Using real-time positioning data from the Raybus and differential DGNSS outdoor positioning systems, it can monitor the positions of the cantilever, telescopic chute, and grab in real time, and use advanced pile shape data collection, filtering, and modeling algorithms to establish a real-time model of the entire ship’s hold pile shape. At the same time, the intelligent pile shape recognition algorithm is used to adjust the control strategy, and the unmanned system computer controls the movement of the corresponding mechanisms of the shiploader through the original PLC system and transmission control system of the shiploader to complete the fully automatic loading operation.

In fully automatic control mode, there is no need for personnel to operate and monitor the shiploader, nor is it necessary to have dedicated personnel in the central control room to operate the entire process. After receiving the fully automatic control signal, the unmanned operating system issues a control enable through the shiploader’s built-in programmable control system and drives the operation of the shiploader’s trolley, pitch, cantilever lift, telescopic, telescopic chute, and other mechanisms. When the actual position values of the shiploader’s telescopic chute and bucket are about to reach the set alarm values, the shiploader’s unmanned control system outputs a signal to enable the frequency converter of the above-mentioned mechanisms to reverse the motor, moving the corresponding mechanisms away from the alarm range to ensure the safe operation of the equipment.

Telescopic Chute Designed by GBM With Safety Performance

As a leading manufacturer in the field of port handling equipment, GBM deeply understands the extreme importance of the safe operation of shiploader telescopic chute mechanisms. Its telescopic chute product line design systematically integrates and innovatively optimizes the multiple safety protection technologies discussed in the previous sections, significantly improving the safety performance and reliability of the equipment.

The core safety advantages of GBM chutes are reflected in the following aspects:

Multiple sensing and intelligent anti-collision system:

GBM telescopic chutes are equipped with high-precision tilt switches and bottom tilt switches as standard. Once the system detects that the safe distance from the ship’s hull or material pile is approaching a critical value, it immediately triggers a multi-level warning (audible and visual alarm) and automatically performs emergency avoidance actions (such as stopping movement or reversing operation), upgrading from “passive response” to “active prevention” and greatly reducing the risk of collision.

Enhanced structural safety design:

Steel wire rope safety: Drawing on mature experience, the GBM telescopic chute adopts an improved steel wire rope connection method and sets up a balance locking device at key points. This design ensures that even if a single steel wire rope breaks accidentally, the balance locking device can effectively support the weight of the lower telescopic chute, preventing it from falling apart and gaining valuable time for emergency repairs, eliminating major fall hazards.

Comprehensive blockage prevention and disposal:

Intelligent blockage monitoring: Highly sensitive blockage switches are installed at key locations in the cantilever head hopper, combined with possible pressure or flow sensors inside the telescopic chute, to achieve early and accurate detection of blockages.

Interlock protection: Once a blockage is confirmed, the system immediately sounds an alarm and stops loading through an electrical interlock to prevent equipment damage and further accidents.

Summary

Ensuring the safety of the shiploader telescopic chute mechanism is a systematic project involving design, manufacturing, application control, and maintenance. The continuous application and innovation of safety protection technology, especially in the direction of intelligence and automation, and the selection of equipment with integrated high safety standards, are the inevitable choices for port enterprises to improve their intrinsic safety level and achieve safe and efficient production. In the future, with the further development of sensor technology, artificial intelligence, and remote control technology, the safety protection of the telescopic chute mechanism will reach a higher level.

Please kindly contact us sales.export@gbm-china.com for the free technical support.