Overview

Current Pollution Situation

A grab is a type of port handling machinery that uses a movable bucket to load and unload bulk cargo. It primarily relies on two combined buckets on either side to load and unload bulk materials. Common bulk materials handled by grabs include lightweight materials such as grains, neutral materials such as sand and gravel, and heavy materials such as iron ore.

The use of grab bucket technology in port bulk cargo handling is a common port transportation operation method. This method is convenient and flexible; however, since the bulk cargo handling process is an open-air operation, dust pollution is significant during the falling process of bulk cargo, especially when windy conditions occur, leading to severe pollution.

When the grab bucket opens to unload, bulk cargo materials such as cement, sand and gravel, and iron ore fall under the influence of gravity. As large quantities of bulk materials fall, the downward movement creates a displacement effect on the air encountered during descent, causing the airflow to move upward while the bulk materials fall downward. This creates a certain buoyancy effect on the bulk materials. Larger particles with higher density are less affected, but smaller particles with lower mass and density suspend in the air and disperse, forming dust pollution.

To control dust pollution at the grab unloading point, measures such as installing wind baffles above the grab to reduce the material’s descent height during unloading, or installing dust collection hoods on the sides of the hopper followed by dust collectors for treatment, can be taken. When materials are prone to degradation due to water exposure, dust suppression methods such as water sprinkling or misting can also be employed.

Main Prevention Measures and Current Status

Currently, the primary dust control technologies for grab buckets worldwide can be broadly categorized into three types: process improvements to the grab bucket hopper, wet dust suppression, and dry dust collection.

Process improvements to the grab bucket typically involve installing wind baffles around the hopper, allowing the grab bucket to unload beneath the baffles, which effectively reduces dust pollution. However, this method requires high operational proficiency from grab bucket machine operators and is challenging to implement in practice.

Wet dust suppression includes water spraying or misting for dust suppression and wet dust collectors. Water spraying or misting generally achieves good results, but it can wet the material, affecting the quality of bulk materials, and wet material can have a corrosive effect on transportation equipment. Excessive water spraying can also cause runoff wastewater, which requires further treatment. Water spraying and misting methods are quick to take effect and require less investment, but they consume a significant amount of precious water resources. Runoff wastewater can also cause water pollution issues, and management is not very convenient.

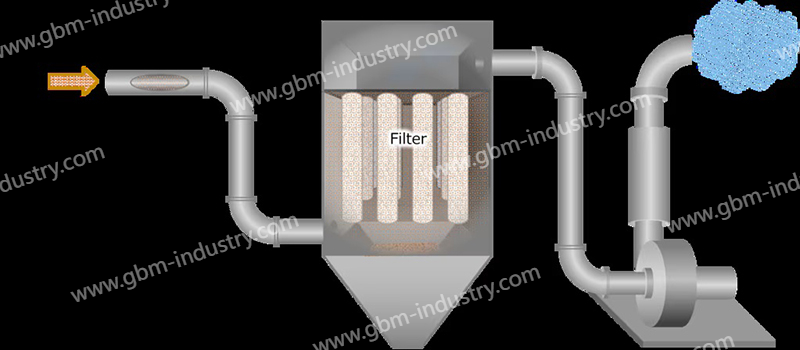

Dry dust removal involves installing dust collection hoods and ducts on the unloading hopper, creating a negative pressure around the hopper to draw dust-laden air into a baghouse dust collector for filtration. The advantage of this dust removal method is that it does not cause water pollution, but it generally requires modifications to the hopper, making design and construction relatively complicated. For special hoppers such as mobile hoppers, it is often necessary to consider designing an insertable baghouse dust collector during the hopper production process, which involves a more intricate design.

Port Dust Control Technology

Water Spraying

Water spraying primarily increases the moisture content on the surface of bulk materials such as coal, ore, and sand and gravel. It also humidifies the air, increasing the concentration of water molecules, which collide with and adsorb dust particles, forming larger particles that settle more quickly. This is a cost-effective dust control method in wet dust collection, characterized by high efficiency, simplicity of operation, and broad applicability.

However, excessive water spraying can lead to runoff wastewater issues, which must be treated before discharge or reuse. Natural weather conditions such as strong winds often affect the effectiveness of water spraying.

Mist Sprayer

The mist sprayer atomizes water into droplets of the same size as dust particles. Since the droplet particles and dust particles have similar or identical diameters, dust particles become moist as they come into contact with the droplets during gas flow. The moist dust particles continue to adsorb other dust particles, gradually coagulating into particle clusters. These dust particle clusters settle due to their own gravitational force.

Mist sprayers have a long spray range and cover a large area. They can be directly connected to tap water or use recycled water such as treated wastewater. They are effective against dust particles of various sizes and diameters. The moisture content of the material increases with the spray volume, and they also have a good preventive effect against secondary dust generation in subsequent material handling processes. The maximum spray range of the mist sprayer varies by model, with ranges reaching 40–120 meters and maximum coverage areas of 4,500–27,600 square meters.

For dust pollution generated during grab unloading, which is difficult to contain due to its open-air nature, mist spraying is an effective control method. Key features include high initial investment costs, ease of operation, and the fact that natural weather conditions such as strong winds can affect spray effectiveness.

Baghouse Dust Collector

When the grab handles hydrophilic materials such as cement or bulk grain, and spraying water is not suitable, a baghouse dust collector solution can be adopted. When designing this solution, a closed dust collection hood is typically installed above the grab around the perimeter, with the dust collected through ductwork connected to the baghouse dust collector.

A baghouse dust collector is a filtration-type dust collector. It is suitable for capturing fine, dry, non-fibrous dust. The filter media used in baghouse dust collectors are diverse, categorized by material into natural fibers, inorganic fibers, and synthetic fibers; and by filter material structure, there are two categories: filter cloth and felt. During dust collection, the filtering effect of fibrous fabrics is utilized to filter dust-laden gas. When dust-laden gas enters the interior of the baghouse dust collector, larger particles with higher specific gravity settle due to increased cross-sectional area and reduced dust velocity, falling into the hopper. Meanwhile, the gas containing finer dust particles passes through the filter bags, and as it flows through the pores of the filter material, the dust particles are captured on the filter material. The clean gas that passes through the filter material is discharged through the outlet.

Filter bags are typically cleaned using compressed air for pulse jet cleaning. During the cleaning process, the solenoid valve opens the pulse valve, and compressed air is sprayed through the cleaning control device according to the set program. Compressed air is injected into the filter bag chamber through each pulse valve in sequence at extremely short intervals, creating an air wave that causes the filter bags to simultaneously expand and undergo mechanical vibration, resulting in strong cleaning action to remove dust accumulated on the outer surface of the filter bags.

The advantages of this scheme are: it has a strong targeted effect on materials where dust and water are prone to react, achieving high dust removal efficiency and enabling the recovery of dust materials for secondary use. The disadvantages are: it can only capture dust from the hopper, and is ineffective against dust scattered during the back-and-forth movement of the grab; When used in rainy or snowy weather, the high moisture content in the dust-laden gas can cause condensation inside the dust collector, blocking the filter bags and the ash discharge system. Severe dust accumulation may affect the operation of the main dust collector unit, so it is recommended to cease operations during rainy or snowy weather; The grab bucket unloading is intermittent, but the dust collector and motor must remain continuously operational, increasing power consumption.

The insert-type baghouse dust collector

The insert-type baghouse dust collector uses flat bag filters, which have the largest filtration volume per unit volume. Therefore, under the same filtration area, it has a smaller volume and can be conveniently installed in any structure. Since this type of dust collector can be installed near the pollution source using an insert-type installation method, it not only saves installation space but also reduces duct installation costs. Depending on the direction of dust dispersion, the filter bags can be installed vertically, horizontally, or using integrated technology. The insert-type baghouse dust collector, with its insert-type design, is particularly suitable for warehouses, hoppers, coal silos, and other storage facilities, saving duct installation costs. The filter bags can be installed vertically or horizontally.

In dust control applications involving grab buckets, the use of baghouse dust collectors often results in larger dust collector volumes and higher power consumption, especially when the hopper is a mobile hopper, making it difficult to install a fixed dust collector. In such conditions, the insert-type baghouse dust collector is particularly suitable for mobile hoppers where the dust collector’s installation area and volume are restricted.

The advantages of this solution are: since the dust intake is located near the dust generation area, the duct resistance is low, achieving the same dust removal effect with significantly lower airflow compared to conventional dust collectors, resulting in high dust removal efficiency and a smaller fan motor power. The disadvantage is that the insert-type baghouse dust collector must be designed in conjunction with the hopper. An automatic dust-proof curtain is typically installed above the hopper, and the hopper and insert-type baghouse dust collector are generally designed as an integrated dust collection hopper, which is relatively expensive on the market.

Wet dust collectors and other dust collectors

For non-hydrophilic dust, wet dust collectors can also be used. Their advantages include: simple structure, low cost, high purification efficiency, and suitability for purifying various types of dust that are non-fibrous and do not react chemically with water.

Compared to dry dust collectors: Compared to the complex structure of baghouse dust collectors, wet dust collectors have a simpler construction, resulting in lower equipment investment, higher purification efficiency, and the ability to remove dust particles larger than 0.1 μm; there are no moving parts inside the equipment, resulting in a lower failure rate; compared to baghouse dust collectors that require external compressed air for cleaning, wet dust collectors only require water supply, which is easier to manage. The drawbacks are: it consumes a certain amount of water; dust treated into slurry cannot be recycled; sticky dust can cause blockages in the dust collector’s wastewater pipes; frost protection must be considered in winter; and it generates a large amount of dust-laden wastewater, which is difficult to treat. Therefore, wet dust collection is suitable for handling various types of dust that do not react chemically with water or form adhesions, and for southern factory areas with convenient wastewater treatment facilities.

Dust Removal Design of GBM Bulk Material Grab

During bulk material handling, the GBM grab features a proprietary sealed cover plate on the upper part of the grab body, which effectively implements an active dust removal solution.

3.1 When the grab is closed, the cover plate follows the movement of the jaw plate, forming a nearly sealed space, thereby effectively suppressing dust generation and dispersion at the source of material handling and lifting. This significantly reduces air pollution in the terminal area, improves the working environment for operators, and helps the port comply with stringent environmental regulations.

3.2 As a physical barrier, the cover plate completely resolves the issue of material (especially lightweight, powdery bulk cargo) spilling out from the top due to grab bucket vibrations or wind influence, maximizing the reduction of unexpected cargo loss during loading and unloading. This directly preserves economic benefits for customers, achieving dual benefits of environmental protection and cost control.

Conclusion

Environmental protection is an important component of sustainable development, and dust pollution at ports is increasingly receiving attention. Dust generated during grab unloading at bulk cargo ports is often open and difficult to control, causing significant pollution at bulk cargo terminals. Therefore, in the design of dust pollution control systems for bulk cargo ports, it is essential to consider the characteristics of bulk cargo materials and grabs to design a reasonable dust collection system.