Wire ropes are extensively utilized in the hoisting, luffing, and trolley traction mechanisms of container STS cranes. As the primary flexible component in container STS crane operations, they offer advantages such as high load-bearing capacity, excellent flexibility, smooth transmission, impact resistance, noise-free operation during high-speed movement, and reliable safety. With advancements in container crane manufacturing technology, current development trends lean toward larger sizes, higher speeds, and greater efficiency. As the reach of STS cranes increases and lifting capacities grow, issues such as sagging due to self-weight and significant spring back during startup have become apparent in long-distance wire rope transmission. Selecting and utilizing appropriate wire ropes has thus become a critical research topic for STS crane management personnel.

Components of Steel Wire Ropes

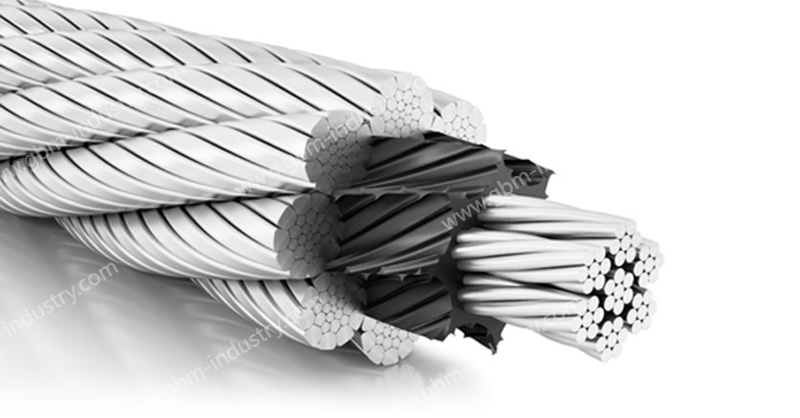

A steel wire rope is a cable formed by twisting multiple steel wires according to specific rules. It consists of rope-making wires, a core, and rope grease. The primary components of a steel wire rope are: twisting method, contact state, number and shape of strands, and core material.

Stranding Methods

Currently, there are three types: single-strand, double-strand, and triple-strand wire ropes. Among these, single-strand and double-strand ropes are most common.

1.1.1 Single-Strand Wire Rope: Formed by winding multiple wires into a rope in a single process. Characterized by high rigidity and poor coiling properties.

1.1.2 Double-lay wire ropes: Double-lay wire ropes can be further classified into co-rotational (same-direction lay) and cross-rotational (opposite-direction lay) structures. Co-rotational wire ropes offer superior flexibility, reduced wear, and longer service life, but are prone to loosening, twisting, and knotting. They are generally used only with rigid guides or when the rope ends cannot rotate freely. Cross-laid wire ropes feature strands twisted in opposite directions relative to the rope, making them less prone to loosening, twisting, or knotting. However, they exhibit slightly greater stiffness and a shorter service life. Cross-laid wire ropes are predominantly used in container STS cranes.

Wire Contact Conditions

Within a rope strand, the contact between adjacent layers of wires can be categorized as point contact, line contact, or surface contact.

Point Contact: Strands with differing twist pitches within a lay interlock, creating point contact at each intersection. This results in high contact stress and secondary bending stress. Point-contact ropes exhibit good linearity but poor bending fatigue resistance, leading to shorter service life. They are gradually being replaced by line-contact ropes.

Line Contact: Strands within a rope are twisted in parallel throughout their entire length. Outer-layer wires lie within grooves formed by inner-layer wires, creating line contact.This configuration features low contact stress, excellent bending fatigue resistance, a compact structure, high metal cross-sectional utilization, and an average service life 1-2 times longer than point-contact ropes. Common types on STS cranes include 6xWS(31) and 6xWS(36).

Surface Contact: The wires within the strands are shaped through special extrusion or wire drawing processes, resulting in surface-to-surface contact between them. Advantages include reduced susceptibility to wire breakage, good corrosion resistance and wear resistance, and the ability to withstand significant lateral forces. However, flexibility is poor, making them unsuitable for installations involving reverse winding or small pulleys.

Number and Configuration of Wire Rope Strand

Common strand configurations for STS cranes include 6-strand, 8-strand, and 9-strand, with 6-strand being the most prevalent. A higher number of outer strands improves contact between the rope and pulley/drum grooves, extending service life.8-strand ropes have a lower metal fill ratio, resulting in a breaking strength approximately 10% lower than 6-strand ropes of the same diameter. However, they offer superior abrasion resistance and service life. Consequently, many users now employ 8-strand rope configurations in the hoisting systems of STS cranes.

Wire Rope Core Materials

Based on core material, wire ropes primarily fall into two categories: fiber core and steel wire core.

Fiber Core (FC): Fiber cores commonly use natural fibers like sisal (NF) or synthetic fibers like polypropylene (SF). They offer good flexibility and elasticity with excellent oil retention, but exhibit poor resistance to lateral pressure and high temperatures, along with inferior support stability. Therefore, they are unsuitable for multi-layer winding systems or cranes operating in high-temperature environments.

Steel Wire Rope Core (SWRC): Features wire ropes or strands as the core. This type offers high strength, withstanding greater pressure and higher operating temperatures. However, it has poor oil retention, flexibility, and elasticity.

New Special Steel Wire Ropes

In recent years, foreign manufacturers have developed novel plastic-filled steel wire ropes. These incorporate a steel core impregnated with specialized plastic, which is then braided with outer steel wires. This design combines the advantages of fiber-core and steel-core wire ropes, reducing internal friction while enhancing structural stability. It significantly improves internal lubrication and corrosion resistance without diminishing metal surface area, thereby maintaining load-bearing capacity.

Selection of Wire Ropes

Different wire types and core configurations can produce diverse rope variants. Given the complex manufacturing processes and diverse application environments, selecting appropriate wire ropes is a specialized task for container cranes. It is a critical consideration for enhancing STS crane efficiency and controlling operational costs.

Selection of Wire Rope Structure

Typically, wire ropes used in winding systems (dynamic ropes) should prioritize strand-contact core wire ropes. To prevent rope loosening and twisting, interlocked-lay wire ropes are generally recommended. When using unidirectional-lay wire ropes, the lay direction should oppose the spiral groove direction of the drum.

The surface condition of the wires and the nominal tensile strength are mutually constrained. Selecting high-strength wires can reduce the wire rope diameter, but this decreases the wire rope’s toughness and increases its stiffness. For domestically produced wire ropes, strength grades of 1570 MPa to 1770 MPa are recommended; for imported wire ropes, the 1770 MPa strength grade is preferred.

Wire Rope Failure Modes and Usage Precautions

Wire Rope Failure Modes

Under normal operating conditions, new wire ropes generally do not experience sudden breakage unless safety devices malfunction or unexpected mechanical accidents occur, causing the load to exceed the rope’s ultimate breaking strength.

The typical failure process and characteristics of STS crane wire ropes are as follows: As the wire rope passes through the winding system, it undergoes repeated bending and even straightening, while also experiencing friction with pulleys or drum grooves. The more severe the working conditions and the more frequent the operation, the more pronounced this phenomenon becomes. Over time, the wires within the rope strands develop varying degrees of bending fatigue and wear. Surface wires gradually fracture. When the number of broken wires reaches a critical threshold, the wire rope loses its load-bearing safety margin and must be scrapped and replaced.

Precautions for Wire Rope Use

Wire ropes are consumable components of cranes. Proper usage primarily involves optimizing the design of the winding system and improving contact and lubrication conditions for the wire rope.

For the hoisting, variable radius, and traction mechanisms of STS cranes, prioritize the use of line-contact wire ropes, surface-contact wire ropes, or new multi-strand (6 strands or more) surface-contact core-filled (or core-wrapped) plastic-coated wire ropes. Select an appropriate wire rope structure based on the primary failure modes observed in STS crane wire ropes. If wire rope fatigue failure primarily involves strand breakage due to bending, 8-strand or 9-strand surface-contact wire ropes may be used while ensuring safety factors are maintained. For wire ropes with service cycles exceeding one year, high operating frequencies, or severe environmental corrosion, plastic-filled or plastic-coated wire ropes are recommended.

Design of STS crane winding systems should minimize wire rope bending cycles, particularly avoiding reverse bending. Experiments demonstrate that reverse bending causes twice the fatigue damage compared to unidirectional bending.

Where feasible, select pulleys and drums with larger diameters (D) to increase the rope diameter ratio (D/d), thereby reducing rope bending and contact pressure.The deviation angle between the sheave or drum and the wire rope, known as the rope exit angle, directly impacts the wire rope’s service life.

Appropriately increasing the distance between sheaves and reducing the wire rope’s speed through sheaves both contribute to extending the wire rope’s service life.

Prevent mechanical damage caused by wire rope collisions with equipment components such as guide container channels and bulkheads during operation. Avoid human-induced factors like welding sparks directly falling onto the wire rope surface during maintenance.

Specializes Providing Spare Parts for STS Cranes

As a specialized supplier of STS crane wire rope spare parts, GBM delivers exceptional products and services to ensure the efficient operation of port equipment.

Our core strength lies in stringent quality control. We select premium wire rope materials with high strength and wear resistance, combined with mature, advanced processing techniques. This ensures each wire rope possesses outstanding fatigue resistance, corrosion resistance, and overload capacity, guaranteeing the safety and reliability of STS crane operations from the source.

Addressing the urgent demands of continuous port operations, we maintain a comprehensive inventory system with diverse categories and specifications. This enables rapid order fulfillment, significantly shortening delivery cycles and minimizing equipment downtime, thereby creating greater value for our customers.

Furthermore, GBM offers industry-leading extended warranty periods and a highly efficient, professional after-sales service team. We provide full-spectrum support from technical consultation to installation guidance, ensuring worry-free operations and establishing ourselves as your trusted long-term partner.

Conclusion

With the development of the container industry globally, the design and manufacturing technology of steel wire ropes continues to advance. As specialized products, container crane wire ropes will also undergo continuous updates, improvements, and breakthroughs. The proper and rational selection of wire ropes, the exploration of optimal configurations balancing performance and value, and the pursuit of maximized management efficiency and economic benefits—along with the accumulation of experience through these efforts—constitute a critical subject for engineering and technical managers in container enterprises. This encompasses not only production technology but also management techniques.

If you have any requirement,please feel free to contact us for free Consultation:sales.export@gbm-china.com