The remote control and automation upgrade of unloaders is a crucial component of smart port construction. The remote control upgrade primarily involves relocating the operator’s cabin from the worksite to an office building, thereby improving the working environment and reducing operational intensity. Factors such as driver discomfort caused by changes in the operating environment, iterative upgrades of remote control programs, and instability of remote control cameras and other hardware have led to remote control unloading efficiency being lower than that of on-site unloading from the operator’s cabin. By analyzing the factors affecting unloading efficiency during remote operations from multiple angles, and adopting appropriate technologies and improved management measures, the efficiency of remote control operations for unloaders can be enhanced, achieving the goal of improving quality and efficiency.

Analysis of Ship Unloader Operations

Remote control encompasses all functions of the driver’s cabin control panel, including fixed-position camera monitoring functions for 20 control points of main mechanisms such as lifting, opening/closing, trolley, and gantry operations, as well as crane information system functions. After the vessel berths, during the opening and leveling stages, the remote control fully automatic mode is used. Based on the scanned material contour, the system prioritizes selecting the higher material surface in the middle for automatic material handling. Once the material surface is largely leveled, the system automatically selects material handling points within the hatch opening projection area based on the material handling strategy. Finally, when it is necessary to hoist the cargo-cleaning machinery, the unloader operates in remote manual mode or remote semi-automatic mode until the operation is completed.

Statistical comparisons are made between on-site operation and remote control operation data for the unloader. At present, under various ship types, the average single cycle time for remote control is 6.62 seconds longer than on-site operation, and the average operational efficiency is 155 L/h lower.

To identify the time differences between various cycles such as the horizontal movement of the trolley, the lifting of the grab, and the opening/closing of the grab during each cycle in remote operation, the speed curves of each steps in both manual and fully automatic single cycles are monitored. Analysis of the monitoring data reveals that in fully automatic remote control mode, to ensure safety and reduce the combined movement time of the trolley’s lateral movement and grab bucket lifting/lowering, the automated operation’s cycle path becomes longer, with poor continuity, resulting in a significant increase in single cycle time and lower remote control operation efficiency. In manual local operation mode, since the operator is familiar with the equipment’s performance, they can control safety distances more skillfully during operations, resulting in stronger operational continuity, shorter cycle paths, and shorter operation times per grab. Therefore, there is significant room for improvement in grab path optimization.

In remote-controlled operations, the grab’s pickup point strategy is less flexible compared to local operations, relying solely on pre-set pickup strategies. The pickup points also have deviations, causing uneven material surfaces and making pickup difficult, thereby affecting efficiency.

Methods to Improve Operation Efficiency

Improving the efficiency of remote-controlled operations for ship unloaders primarily involves two aspects: optimizing the operational cycle path and improving the pickup strategy.

Optimizing the operational cycle path

In remote-controlled operations of unloaders, optimizing the operational cycle path is key to improving efficiency. By analyzing the differences in cycle curves between on-site and remote-controlled operations, it was found that the main issue in remote-controlled operations lies in the unreasonable path planning during the two stages: from the grab entering the hatch to the material surface and from the hatch back to the grab. This leads to increased cycle times. The following are specific methods for optimizing the operational cycle path.

(1) Data collection and modeling. Collect on-site operation data from multiple skilled operators, including speed curves and time distributions for actions such as the horizontal movement of the trolley, grab lifting, and grab opening/closing. Utilize big data technology to model the collected data, generating typical cycle path curves as reference benchmarks for path optimization.

(2) Path optimization algorithm. Combine real-time hatch height and material surface distribution information obtained from scanning radar to dynamically adjust the grab’s movement path. By introducing the A* algorithm or RRT algorithm (Rapidly Growing Tree algorithm), generate a safe and efficient path. Simulate the actions of skilled operators to reduce the time interval between actions and improve action continuity.

(3) Safety Distance Control. While optimizing the path, adjust the safety distance between the grab, hatch, and material surface. By introducing safety constraints (such as minimum distance thresholds), the path planning algorithm dynamically adjusts the grab’s movement trajectory in real time to avoid collision risks.

(4) Real-time adjustment and feedback. During operations, sensors monitor the grab’s position and speed in real time, and PID control algorithms dynamically adjust motion parameters to ensure the accuracy and stability of path planning.

(5) Establish a feedback mechanism to feed back cycle time and efficiency data from each operation to the path planning system, and continuously optimize the path algorithm using AI algorithms.

After analysis, movement adjustments are made. When the cart moves laterally, the grab is automatically started to rise and descend 2–3 seconds in advance, forming an arc-shaped grabbing curve to shorten the overall cycle time.

Improved grabbing strategy

Diversified grabbing strategies are designed based on the characteristics of different operational stages, and the grabbing points are dynamically adjusted based on real-time scanning data to improve grabbing efficiency and stability.

3.2.1 Multi-stage grabbing strategy design

(1) Opening stage. During the initial opening phase, when the material surface is high and unevenly distributed, a “center-priority” grabbing strategy is adopted to prioritize grabbing the higher central material surface, rapidly reducing the pile height.

(2) Leveling stage. After the material surface is largely leveled, a “uniform distribution” grabbing strategy is adopted. Based on material surface distribution information obtained from the scanning radar, grabbing points are automatically selected to ensure uniform material surface descent.

(3) Bins clearing stage. During bins clearing operations, an “edge-priority” grabbing strategy is adopted, prioritizing the grabbing of residual material at the edges of the bins to create conditions for the insertion of bins clearing machinery.

Dynamic grabbing point selection

Real-time three-dimensional distribution information of the material surface is obtained via scanning radar, combined with deep learning algorithms (such as Convolutional Neural Networks, CNN) to predict the optimal grabbing points. During the grabbing process, the grabbing point is dynamically adjusted based on changes in the material surface to avoid difficulties caused by uneven material surfaces.

Grabbing Force Control Optimization

Force sensors are used to monitor the grabbing force of the grab in real time, and fuzzy control algorithms are combined to dynamically adjust the magnitude of the grabbing force, ensuring stability and efficiency. Different grabbing force control parameters are designed for different material characteristics (such as particle size and moisture content) to enhance adaptability.

Grab Force Control Optimization

A multi-strategy switching mechanism is implemented in the remote control interface, providing operators with multiple grab strategy selection options, supporting both manual and automatic switching. Based on the operational phase and material surface distribution, the system automatically recommends the optimal grab strategy and allows operators to adjust it according to actual conditions.

Experimental Validation and Effect Analysis

To validate the effectiveness of the above methods, seven ship unloaders at a certain port were upgraded for remote operation efficiency improvement, and data before and after the upgrade were compared and analyzed.

Efficiency Comparison

Before the upgrade, the average remote operation efficiency was 1,881 L/h, which increased to 2,075 L/h after the upgrade, representing a 10% improvement in efficiency. The average time per cycle for remote-controlled operations decreased by 4.4 seconds, which is comparable to on-site operations. In operations involving 200,000 LCAPE-class vessels and 400,000-ton vessels, the efficiency exceeded that of on-site operations.

Path Optimization Effects

By optimizing the grab cycle path, the combined movement time of the trolley’s lateral movement and the grab’s lifting and lowering increased, improving operational continuity. The adjusted trolley speed control curve is smoother, resulting in a significant reduction in cycle time.

Grabbing Strategy Improvement Effects

The application of a multi-stage grabbing strategy significantly improves grabbing efficiency, particularly during the opening and closing of the hatch, where grabbing points are selected more reasonably and the material surface descends more uniformly. The dynamic grabbing point selection mechanism effectively avoids grabbing difficulties caused by uneven material surfaces, enhancing operational stability.

GBM Offer Strong Support for Grab Unloader Operations

In demanding grab unloading operations, GBM brand mechanical grabs demonstrate unique advantages through their exceptional design and craftsmanship.

GBM’s Core Advantage

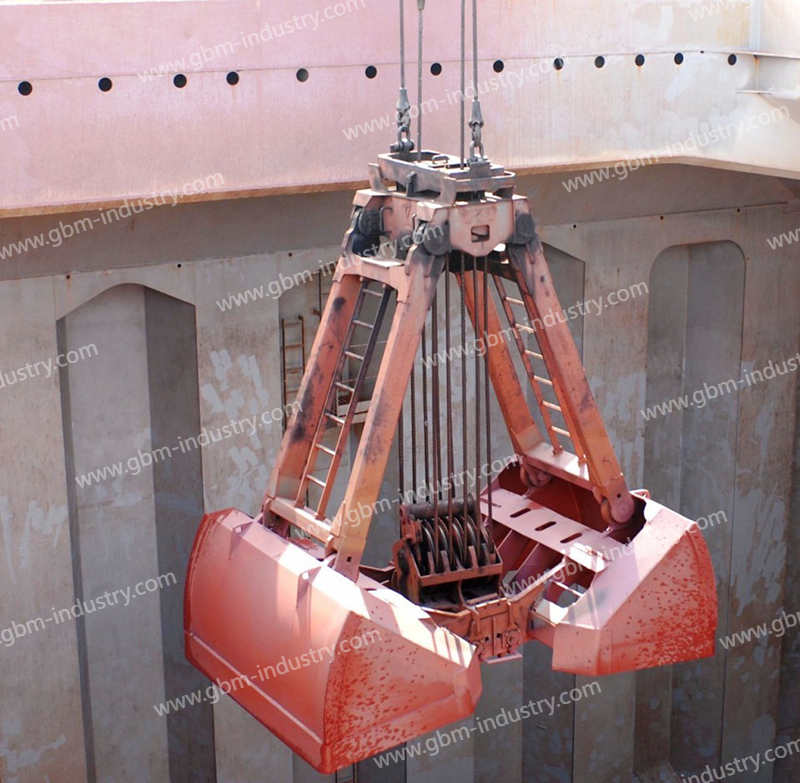

GBM grabs are constructed using high-strength steel, with all critical welded joints undergoing rigorous non-destructive testing to ensure the overall steel structure is robust and reliable, capable of withstanding the high-intensity, continuous impact loads typical of port operations, and ensuring long-term durability.

GBM’s Innovative Design For Operations

Optimized pulley layout and high-precision bearings significantly reduce operational resistance and friction loss, enabling smoother steel rope movement and more efficient force transmission. This significantly enhances overall lifting efficiency during grabbing, lifting, and unloading operations, thereby shortening the operational cycle.

Leak-proof Design For Reduce Material Loss

Through a precise double-leaf closing structure, wear-resistant seals, and optimized jaw plate curves, the grab ensures a tight seal when closed, maximizing prevention of material (especially powdery or small-particle bulk cargo) spillage during grabbing, lifting, and movement, significantly reducing cargo loss and environmental pollution risks.

Conclusion

Improvements in the remote control operation efficiency of ship unloaders provide technical support for the automation upgrade of ship unloaders in the bulk cargo sector, playing a positive role in promoting the modernization and transformation of port development, as well as the construction of smart and green ports.