Grain, also referred to as cereals, encompasses wheat, corn, oats, buckwheat, barley, rice, legumes, seeds, and processed products that retain the same characteristics as grain in its natural state.

Advantages of Grain Shipping

The economic benefits of bulk grain shipping are highly evident.

Beyond significant cost savings, bulk grain shipping substantially reduces transit time by eliminating packaging processes. It also maximizes cargo capacity by removing packaging volume, thereby increasing the total grain transported.

Characteristics of Grain Shipping

For maritime grain transport, aside from partial bagged shipments and limited containerized bulk, the predominant method is specialized bulk carriers. Bulk grain shipping offers advantages including reduced packaging costs, increased cargo capacity, facilitated mechanical loading/unloading, and shorter handling times. For years, bulk grain shipments have consistently ranked among the world’s major dry bulk commodities. The primary characteristics of bulk grain shipping are as follows:

Self-Heating

Grain possesses inherent vitality. Through aerobic and anaerobic respiration, moisture and carbon dioxide levels within the grain continuously rise, generating heat. Improper handling can lead to heat accumulation and condensation, causing grain spoilage.

Hygroscopicity and Despicability

Grain can absorb and release moisture. When moisture content exceeds certain limits, it intensifies respiration and promotes microbial and pest proliferation, leading to self-heating and spoilage.

Adsorption

Grain readily absorbs or adsorbs odors and harmful gases, and once contaminated, these are difficult to remove.

Susceptibility to Pests

Grain is highly vulnerable to infestation during storage. Pests such as grain weevils and weevils readily contaminate grain. If infestation occurs and is not promptly addressed, pests multiply rapidly, compromising grain quality.

Both bulk and bagged grain share these four characteristics. However, bulk grain possesses two additional properties closely related to vessel stability:

Flowability

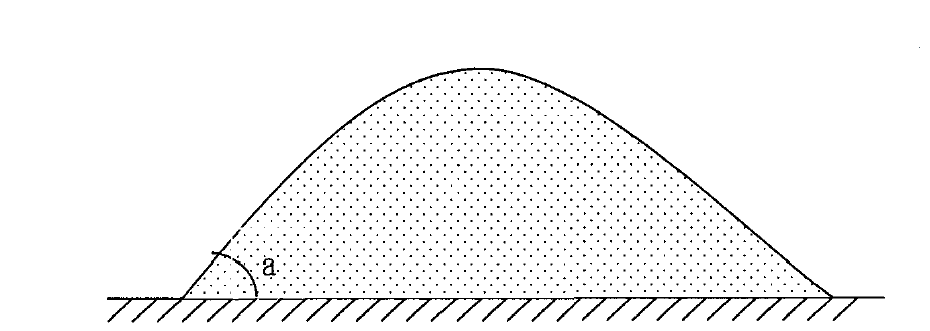

Granular, lumpy, or powdery bulk cargoes—including grain stored in ship holds—exhibit the property of self-loosening and flowing under external forces like ship rolling and vibration. Grain flowability depends on factors such as particle shape, surface smoothness, moisture content, and impurity levels. The degree of free-flowing behavior in bulk grain can be expressed by the angle of repose (natural inclination angle). This refers to the angle formed between the edge line of a cone naturally formed by grain slowly falling from the air onto the ground and the horizontal plane (as shown in the figure).

The schematic of Grain scattered.

Evidently, the smaller the angle of repose of bulk cargo, the greater its free-flowing tendency.

Settling Properties

When bulk grain is loaded into a ship’s hold, the vessel’s rolling and vibration cause the voids between grain particles to gradually decrease, leading to the characteristic sinking of the grain surface. The settling tendency of bulk grain is influenced by factors such as grain particle size, shape, stowage factor, moisture content, and tendency to scatter. Settling within the hold causes the grain’s center of gravity to descend while simultaneously lowering the grain surface, transforming an initially fully loaded state into one with a free grain surface. This creates conditions conducive to scattering. For bulk grain carriers, merely meeting the minimum stability criteria for general dry bulk carriers is insufficient. Under severe sea conditions, when the heeling moment generated by grain movement within holds exceeds a certain threshold, the vessel may capsize.

Requirements for Grain Transportation

Given the aforementioned characteristics of bulk grain, shippers must provide a quality certificate with test results or a quality assurance statement indicating the cargo’s condition for each shipment. This document must specifically state the grain’s temperature and bulk density. When transporting moist grain, its moisture content must also be specified. Shipowners should refuse to load grain exhibiting any of the following conditions:

(1) Grain exhibiting spontaneous heating.

(2) Moisture content exceeding 16%, as measured by specialized moisture meters.

(3) Grain infested by warehouse pests, where infestation by flour beetles reaches Grade 1 or higher, or infestation by weevils—regardless of severity—classified by the number of pests (flour beetles and weevils) per kilogram of grain.

(4) Residual fumigants remain undispersed after pest control treatment.

(5) Grain intended for seed use is found to contain weeds upon quarantine inspection.

Overview of Bulk Grain Ship Stowage

The fundamental requirements and methods for stowage planning on bulk grain carriers are similar to those for general cargo ships. However, due to the distinct characteristics of bulk grain and the structural features of the vessel, the focus of considerations during stowage planning differs.

(1) Determining Voyage Cargo Volume

Bulk grain vessels typically operate at full capacity, so the voyage cargo volume should equal the voyage deadweight tonnage. However, due to the large tonnage of bulk grain vessels, when waterway and port draft restrictions apply, the vessel’s total load capacity should be determined based on the maximum allowable draft for the port and waterway.

(2) Allocation of Cargo Volume Among Bulk holds

When determining bulk hold cargo volumes, maximize loading capacity based on hold dimensions and cargo stowage factors, typically leaving only 1–2 partially loaded bulk holds. The selection criteria for partially loaded holds are: minimal impact on longitudinal strength, ease of adjusting the ship’s trim, and ensuring that the heeling moment caused by grain movement in these holds avoids peak values, thereby maintaining ship stability.

(3) Calculating Draft Differences and Verifying Stability

The method and requirements for calculating draft differences are identical to those for general cargo ships. For stability verification, detailed calculations and approvals of stability margin indicators must be performed for vessels of different structures and routes. The stability calculation forms prescribed by port authorities must be completed. Completing these forms involves selecting the most unfavorable loading condition for stability during the voyage. Using the applicable bulk grain carrier shipping rules, the ship’s complete stability margin indicators are calculated. If stability does not meet requirements, various methods and measures should be taken to improve the bulk grain carrier’s stability.

(4) Preparing Stowage Plans

Stowage plans are presented in both front and top views. They indicate the locations of cargo holds, deck-between spaces, and engine rooms, along with the cargo name (or grade), weight, and stowage factor for each hold. Fully loaded holds must be marked “Full” and indicate their trimming configuration. Partially loaded holds require marking of grain stowage depth or void height; multi-deck vessels require marking of common stowage arrangements; holds equipped with anti-shifting devices require detailed annotation of device type, location, and specific dimensions.

Recommend For Grain Transport Development

Ensuring Grain Quality During Transportation

Based on the characteristics of bulk grain shipping outlined above, the following measures should be implemented to guarantee grain quality.

(1) Preventive Measures Against Grain Self-Heating

Prior to loading, grain moisture content must be inspected. Any grain exceeding specified moisture standards shall not be loaded. Additionally, before loading, verify that the cargo hold is dry and that ventilation equipment is operational. Maintain adequate ventilation throughout transit to prevent heat accumulation and condensation, which can cause grain spoilage.

(2) Moisture Absorption and Desorption Prevention Measures

All grains must undergo strict moisture content checks before loading. However, different grain types require tailored handling based on their characteristics. For example:

– Wheat: Besides strict moisture control, wheat should be sun-dried to reduce moisture below 12.5% before loading. Load while warm and store in sealed conditions. Corn should be loaded into separate holds according to moisture content.

(3) Measures to Prevent Grain Odor Absorption

Grain readily absorbs odors and harmful gases, which are difficult to eliminate once absorbed. Therefore, ensure the ship’s holds are clean before loading. Additionally, during drying, ensure the surrounding environment of the drying site is free from contamination.

(4) Pest Prevention Measures

Inspect grain for insect infestation and conduct hold inspections prior to loading. Should grain pests be detected during transit, fumigate the holds to eliminate them.

Efficient Grain Transportation Solutions

In bulk grain loading, unloading, and transshipment operations, GBM consistently provides efficient, clean, and professional equipment solutions to address challenges of loss and contamination inherent in traditional methods. GBM’s leak-proof grab buckets feature innovative structural and sealing designs that significantly reduce grain spillage and dust during handling.

This not only minimizes cargo loss but also enhances workplace cleanliness and environmental sustainability. Simultaneously, GBM’s bagging machines efficiently and accurately fill bulk grain into packaging bags. The fully enclosed operation effectively prevents contamination and grain leakage, ensuring food safety while meeting customer demands for bagged transportation. The GBM equipment series seamlessly integrates with every stage of bulk grain transportation, providing reliable support for enhancing quality, efficiency, and green operations in maritime grain shipping.