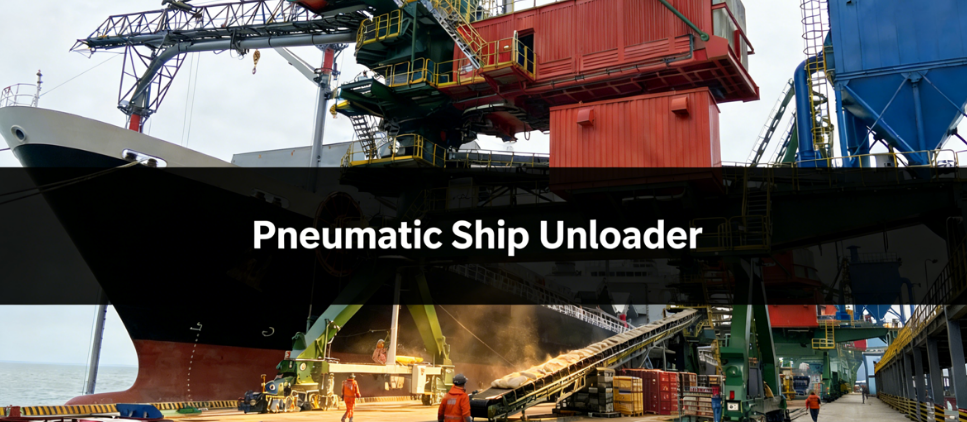

Pneumatic Ship Unloader

The main advantage of Pneumatic ship unloader:

- Fully enclosed transport prevents material loss

Flexible suction arms minimize residual cargo in ship holds

Eco operation and prevents pollution

Easily adaptable to various vessel and terminal

Reduces port space occupation

Pneumatic Ship Uunloader Manufacturer In China

A pneumatic unloader manufactured by GBM is a port discharging equipment that utilizes the pressure differential generated by airflow to convey bulk materials through enclosed pipelines. It is primarily used to unload powdered and granular bulk cargo—such as grain, soybeans, cement, fertilizer, coal powder, mineral powder, alumina, PVC, etc.—from ship holds.

Especially in the specific unloading fields of alumina and cement, pneumatic ship unloaders have become the optimal solution under technical, economic, and regulatory considerations, as their unparalleled environmental advantages and excellent hold-cleaning performance.

Technical Data

- tab1

| Model Class | Rated Capacity (t/h) | Typical Applicable Materials | Suitable Vessel Size (Estimate) | Characteristics & Application Scenarios |

|---|---|---|---|---|

| Small | 200 – 300 | Grain, feed, small-batch chemical raw materials | 3k – 10k DWT | Inland river ports, small grain silos, dedicated chemical plant docks. Relatively low investment. |

| Medium (Most Common) | 400 – 600 | Alumina, cement, soybeans, cassava pellets | 20k – 50k DWT (Panamax) | Largest market demand. Suitable for most specialized bulk terminals. High cost-effectiveness. |

| Large | 800 – 1000 | Large-scale transshipment of grain, alumina | 50k – 80k DWT (Capesize) | Used for national grain reserve bases, large aluminum industry base ports. High efficiency, complex system. |

| Extra-Large / System | 1200+ | Coal powder, bulk grain (requires special design) | 100k+ DWT | Non-standard, mostly customized for special projects. May employ dual-line or multi-line parallel configuration. |

Pneumatic Ship Unloader

If you accept higher energy consumption and investment cost, pneumatic ship unloader would be good choice for high value material.Pneumatic ship unloaders are good at cleanliness, dust control, and gentle handling.

We GBM will consider your material type, required capacity, site constraints, and design the perfect unloading solution for you—efficient, clean, and built to last.

At GBM, we not only sell equipment—we engineer solutions. We will help select the most suitable machine for your operational needs within your budget. From dense minerals to lightweight powders, we deliver custom systems that integrate seamlessly into your workflow.

Pneumatic Ship Unloader

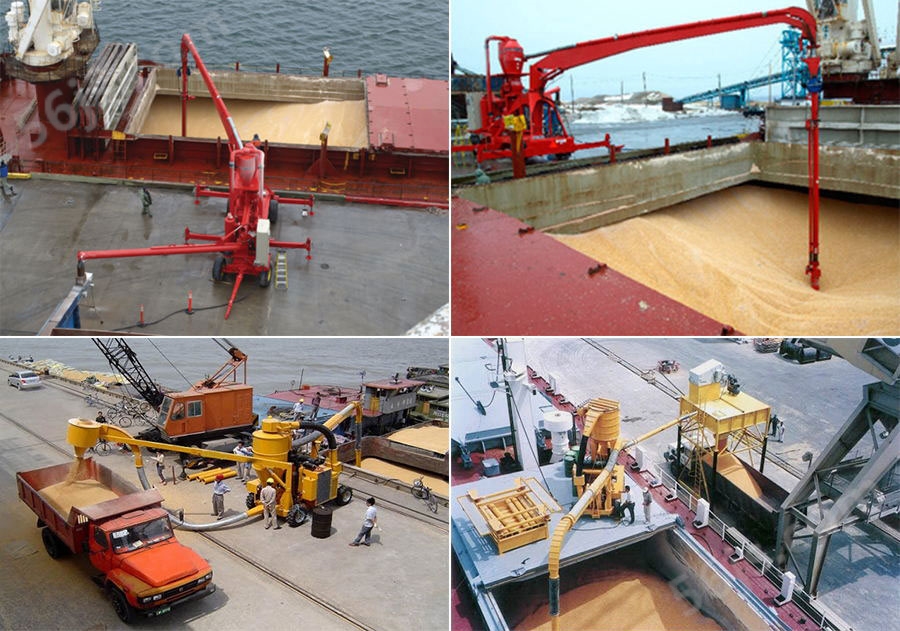

Pneumatic ship unloaders are especially suitable for below material:

- Fine powders: cement, fly ash, silica, alumina

- Lightweight granules: wheat, soybeans, feed grains, cement

- Industrial materials: carbon black, starch, titanium dioxide, chemicals

So nowdays the pneumatic shi unloaders widely used in regions and industries with strict environmental standards and high-value material handling needs:

✅ Dominant in ports handling cement, grains, and eco-sensitive industrial materials.

✅ Growing demand in cement terminals, food processing ports, and chemical logistics hubs.

✅ For dust-sensitive and hygienic unloading of grains and powders.

Pneumatic Ship Unloader

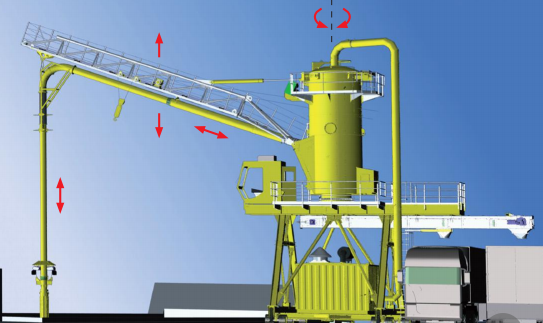

Our pneumatic ship unloader adpot negative pressure system at its intake. This suction head creates a vacuum that gently but powerfully extracts dry bulk solids,and ensuring smooth, continuous material flow directly into the enclosed pipeline.

At GBM,we overcome core technical challenges,we bridging the gap between static ship holds and the fixed pipeline, preventing blockages and optimizing suction efficiency.

Now our pneumatic ship unloader equipped with the daptive suction head,it is automatically adjusts to material and ship.It also equip real-time sensors which adjust airflow and vacuum to handle material changes without labor adjustment.

This innovation will bring operational advantage: please experience the GBM difference in suction technology.

Why Choose GBM As Your Partner?

Pneumatic Ship Unloader Technical Gallery

- Pneumatic Ship Unloader Unloading Aluminum oxide Without Dust

Pneumatic Ship Unloader Global Case

Related Company Catalog

More Eco Unloading Solution Youtube Link ,Please click below:

- Unloading cement by GBM Eco hopper in the Philippines without any dust

- Unloading clinker by GBM Eco hopper in the Kribi without any dust

- Unloading cement by GBM Eco hopper in the Gambia without any dust

- The production process, welding quality, and quality inspection of Eco hopper

- Proffestional Packing details for eco hopper delivery

- GBM ecological hopper and diesel grab working at Japan site

- Preparation before shipment for dust-proof hopper at factory

GBM FACTORY SUPERIOR QUALITY

Quality is the priority of enterprises, GBM accepts this strict challenge. For improve product quality, we ensure strict control from raw material storage to finished product debugging, grasping every process and detail.

.

.